Machining Technology Contributes to Full Manufacturing Facility Status

Established in 1976 with only a saw, a manually operated mill and a lathe, Kosmo Machine Inc. quickly became committed to providing consistent, high-quality products with unmatched customer service. Although Kosmo now provides numerous machining and reconditioning services from its 62,500 square-foot facility, they hesitate to call themselves a machine shop.

Instead, Chief Operations Officer Heath Stewart and his team of 57 employees refer to the Richmond, Virginia, shop as a "manufacturing facility." As such, the employee-owned company supports many industries including defense, aerospace, power generation, shipbuilding and advanced fibers technology. Capabilities include precision machining, certified welding processes, painting and assembly, in addition to multiple reconditioning processes of high-value components.

"To remain competitive on a national level requires being a full-service provider of leading-edge manufacturing technology which is key to our success. We have capabilities under one roof that other suppliers do not, allowing streamlined lead times," said Stewart. "We perform very niche products/parts with high customer service requirements. Our customer’s main goal is to reduce lead times, and they depend on us to help them succeed. We collaborate throughout the planning and manufacturing processes, providing advice and subsequent feedback as we work toward common objectives."

To help Kosmo meet these expectations, Mike Redden, CEO of Kosmo Machine Inc., noted their longstanding relationship with Mazak, an industry-leading manufacturer of precision machine tools. “Mazaks are very robust, they last a long time, and are highly versatile. We keep pace with production demands because of their speed, rigidity, precision and ease of use," Redden said. "Besides this, we’ve built strong relationships with Mazak personnel including sales, service and the applications department. We have worked with several of their employees for many years, some of whom we’ve known for more than 20 years, and that speaks volumes. In the rare instance when a machine goes offline, it is never down for long because of the dependability of our relationship with Mazak. We have built our company around Mazak technology, which continues to contribute to our longstanding success".

Jobs at Kosmo occasionally recur and can involve lot sizes that vary from one piece to over 1,000, but typical jobs involve between 10 and 100 parts. For shipbuilding, the facility produces parts for nuclear-class submarines and aircraft carriers.”

For its work, Kosmo has purchased upwards of 25 Mazak machines ranging from lathes with live tooling, to horizontal and vertical machining centers with 3 and 4-axis milling and those with full 5-axis movement and turning capability for “DONE-IN-ONE” part processing. Models include the Mazak HCN-8800 Horizontal Machining Center with a massive work envelope, HCN-6000 Horizontal Machining Center and VARIAXIS i-600s.

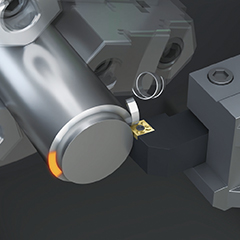

One of the latest additions is a 5-axis Mazak VARIAXIS i-700T with an 18,000-rpm milling spindle and turning capability. The machine is paired with a Mazak 12-station PALLETECH Automation System and Smooth Tool Management software. This software tracks tool data in an RFID chip in the retention knobs of tool holders, which enables the machinist to take tools in and out of the machine without risking data entry errors or loss of tool data.

"Mazak's line of VARIAXIS machines is one of our favorites because of their versatility," said Stewart. "VARIAXIS allows us to turn and mill in a single application and provide full 5-axis motion, they also permit single-setup part production. With the PALLETECH system, we can store fixtures and setups on 12 stations and machine incoming customers' parts based on their demand. That reduces job setup and changeovers to minutes instead of hours. Without our VARIAXIS machines, part production would involve multiple machines and much more labor."

Kosmo's newer Mazaks are equipped with the MAZATROL SmoothAi control. According to Stewart, this control enables them to push machining limits and develop new methods and strategies for metal removal. Furthermore, he noted that Mazak's MAZATROL software always has been a key factor in the facility's decision to stay with the Mazak brand.

"We use MAZATROL for the bulk of our programming and even to streamline the 3+2 programming on our 5-axis machining centers," said Stewart. "G-code is used for our 3D surfacing and full 5-axis motion. On top of that, the controls simplify cross-training, so our machinists can now alternate between machines of different ages and varying types because of the MAZATROL universal programming format."

With Kosmo's mindset of providing quality, productivity and attracting the highest level of customers and skilled personnel, Mazak always has been at the forefront among its choices of machine tools. The facility purchased its first Mazak QT-15 Turning Center with a T-32 control in the early 80s and has relied on the Mazak brand ever since.

Today, Kosmo runs one shift, mainly because of the skilled labor shortage. "We do have a state and nationally accredited in-house apprentice program for machining, which has been beneficial; while our welding curriculum is sourced at a local community college,” pointed out Redden. “The way we contend with this shortage is to invest in technology, such as the Mazak PALLETECH automation system, and strive for more lights-out production which is well suited to the machining of large, highly complex shapes with longer cycle times.”

Kosmo’s skilled staff finish machine 3D-printed aerospace components from Inconel 718, Hastalloy and other difficult-to-machine high-temperature alloys. These mostly engine parts contain complex geometries requiring very close tolerances, ultra-smooth surface finishes and unique fixturing techniques.

“Advancements in 3D additive manufacturing have rewritten the rules for design and engineering, allowing performance-enhanced shapes and functioning internal passages which were impossible to produce until now. These designs often combine multiple parts into just one more efficient component requiring extended machining cycle times,” said Redden.

He also noted a few essential qualities shared by Kosmo and Mazak that have perpetuated success for both companies. The first is maintaining the highest degree of ethics, and the second is to always deliver quality and value on time, every time. Lastly to provide opportunities for employee development and empower all individuals to seek effective challenges and career advancement.