Manufacturers Will Learn How to Drive Results with Innovation at Mazak’s DISCOVER 2025 Event

FLORENCE, Ky., July 9, 2025 – Mazak will showcase its latest innovations during the company’s biennial DISCOVER 2025 event, which will be held October 6-10 at its North American headquarters in Florence, Kentucky. With the broadest display of machine tools in the U.S. and with live demonstrations on over 30 machines within one location, DISCOVER 2025 offers attendees the unique opportunity to experience a full range of productivity-enhancing solutions through four Action Areas: Advanced Machining, High-Volume Production, Multi-Tasking Technology and Shop Solutions. In addition, attendees can take part in keynote and technical panel presentations covering industry trends and best practices, explore Mazak MPower Complete Customer Care services and speak with experts about financing solutions available through Mazak Capital Equipment Financing (MCEF).

“We honor our responsibility to the industry by ensuring DISCOVER directly reflects the trajectory of manufacturing,” says. Dan Janka, President of Mazak Corporation. “As manufacturers across North America navigate a highly competitive and rapidly evolving landscape, Mazak serves as a partner that delivers innovation and demonstrates how to put it into action.”

The Advanced Machining Action Area will spotlight progressive technologies for processing complex parts. For full 5-axis machining, visitors will experience the VARIAXIS C-, i- and i-NEO series of vertical machining centers as well as HCN NEO Series Horizontal Machining Centers.

In the High-Volume Production Action Area, Mazak’s SYNCREX Series of Swiss-type machines for high output of small, precise parts will take center stage along with the company’s HQR 250/3 NEO next-generation high-efficiency, two-spindle/three-turret CNC turning center.

Mazak’s INTEGREX and QUICK TURN Series machines will be on full display in the Multi-Tasking Action Area to show attendees how to increase output and make more with DONE IN ONE® part processing capability. Mazak Multi-Tasking provides maximized machine utilization and single-setup part production, and at DISCOVER 2025 manufacturers can gain firsthand insight into how it improves part quality and accuracy.

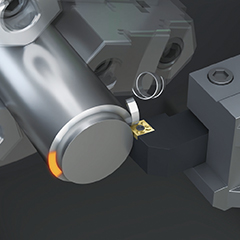

Mazak’s new grinding integration packages for their INTEGREX i-H and HYBRID Series of Multi-Tasking machines will be featured in the Multi-Tasking Action Area. These packages enable automated multi-surface grinding – including outside diameter (O.D.), face, internal diameter (I.D.) and inclined grinding – without manual intervention. The result is enhanced geometric accuracy, superior surface finish and reduced environmental impact. Consolidating operations into a single setup reduces lead times, floor space, the need for outsourcing and overall manufacturing costs while offering the flexibility to adapt quickly to changing market demands.

In the Shop Solutions Action Area, Mazak will demonstrate its cost-effective Ez Series that gives shops of any size access to Mazak reliability and performance. A highlight of this year’s event, attendees will get an exclusive look at the new VTC-Ez Series Vertical Traveling Column Machining Center. Engineered with the Ez compact design and powered by SmoothEz CNC control technology, the new series gives shops more options to maximize production.

All Mazak machines are automation-ready, and DISCOVER 2025 offers production managers, CEOs, and operations directors the opportunity to speak directly with automation experts and discuss how they can integrate scalable automation into their production operations. From customized to standard solutions, such as the Ez LOADER compact cobot automation system and the PALLETECH High-Rise System (PHS), automation unlocks significant output improvements to meet today’s manufacturing demands.

Mazak will also showcase its latest digital innovations in connectivity, monitoring, artificial intelligence, and cybersecurity tools. These technologies offer practical solutions that help shops optimize performance, elevate operational efficiency, and safeguard their intellectual property in an increasingly connected manufacturing environment.

For continued learning and professional development, a dynamic curriculum developed by Mazak manufacturing experts will be available to all event attendees. As a complement to panel discussions and knowledge sharing, tours of Mazak’s own manufacturing facility will be offered throughout the week of DISCOVER 2025. The Mazak iSMART FACTORY™, where Mazaks make Mazaks, provides immersive learning on how technology and digital innovations drive manufacturing results.

The company will also spotlight its industry-leading Mazak MPower Complete Customer Care program that provides end-to-end support for every Mazak machine tool and MCEF, which gives customers access to factory-direct low-cost financing on Mazak machines.