| Chuck size | 6″ |

| Max. machining diameter | Φ7.09″ |

| Max. machining length | 7.87″ |

CNC Turning Center

QT-PRIMOS

- Built-in motor spindle for high-accuracy, high-speed machining

- Less floor space

- Compact automation options to suit your production style

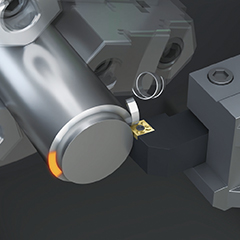

Rigid spindle for unsurpassed machining performance

The built-in motor spindle uses no gears or belts which can cause vibration during machining, which significantly improves roundness and surface roughness. This also eliminates the need to adjust belt tension and replace belts due to wear.

8 position turret for quick indexing

8 Position Drum Turret

The QT-PRIMOS series is equipped with a servo motor driven, drum turret that features high-speed, non-lift turret indexing

QT-PRIMOS 100 SG

| O.D. turning face tool | 20 mm × 20 mm |

| Boring bar | Φ20 mm / Φ25 mm (selectable) |

| Indexing time | 0.2 sec |

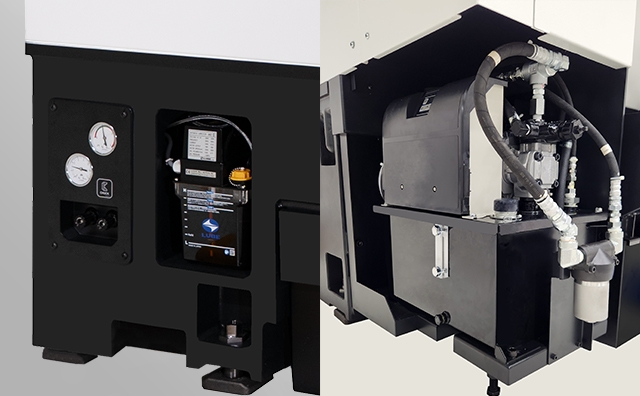

Compact design and easy maintenance

Space-saving design

Compact design improves operator workability. Productivity per floor area is improved.

| 1 | MAZATROL SmoothEz | QT-PRIMOS 50 SG, 100 SG | 1655 mm |

|---|---|---|---|

| QT-PRIMOS 150 SG | 1850 mm | ||

| MAZAK FZ | QT-PRIMOS 50 SG, 100 SG | 1575 mm | |

| QT-PRIMOS 150 SG | 1850 mm | ||

| 2 | 1700 mm | ||

| 3 | 1435 mm | ||

1 | QT-PRIMOS 100 SG | 62.01″ |

2 | QT-PRIMOS 100 SG | 54.92″ |

| 3 | QT-PRIMOS 100 SG | 66.93″ |

| 4 | QT-PRIMOS 100 SG | 56.5″ |

- * Machine dimensions vary depending on specifications

No maintenance required on left/ride sides of the machine

Areas for daily maintenance are designed to be accessible from the front and rear side. It is also useful for installing machines side by side. The lubrication oil tank is located in front of the machine. The other items requiring daily checking are also located in front and back of the machine for easy maintenance when the machines are located in a production line.

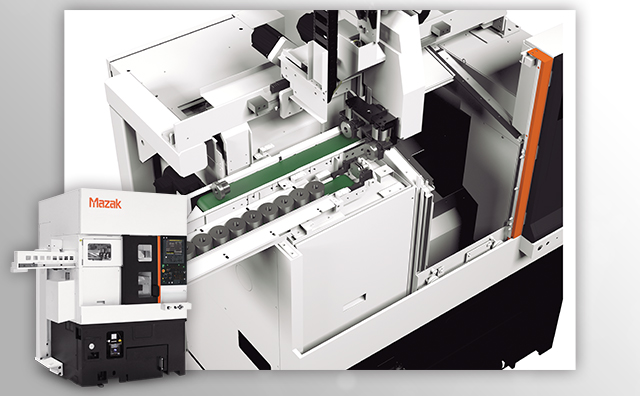

Quick and compact automation options to suit your application

A single second makes a difference in manufacturing.

The automation system of QT-PRIMOS reduces cycle time through rapid axis travel and acceleration/deceleration.

Accurate and precise positioning ensures reliable workpiece attachment and removal.

Quick Loader (Compact floor space automation system)

This automated system is ideal for mass production of a small variety of products. Automation is possible in the same floor space as standard machines. Continuous machining is possible due to automatic loading/unloading. The work output conveyor and work input chute are on the left side of the machine for continuous operation.

Gantry Loader

This automated system is ideal for mass production of a large variety of products. Turn-over Unit (option) can be attached to machines per request. The material / finished workpiece can be loaded on the pallet up to a height of 13.78" to increase unmanned operation. Teaching for gantry loader operation can also be easily done.

Selectable CNC systems

MAZATROL SmoothEz

Intuitive operation with touch screen. Programs can be created while checking the machining shape and processes on the CNC screen, which helps prevent programming errors and shortens programming time.