CNC for Laser Processing Machines

MAZATROL CNC ever evolving with Mazak laser machines

When it comes to laser processing machines, not only the performance of the machine itself is important, but also the control technology, operability and network. Over the past 30 years, the Mazak CNC systems have evolved with advanced technology, leading to the development of dedicated systems for 2D and 3D laser processing machines. With the system, the Mazak laser machines can be operated at their full potential at all times.

CNC control for 2D laser processing machines

Large 21.5” LCD screen and touch panel

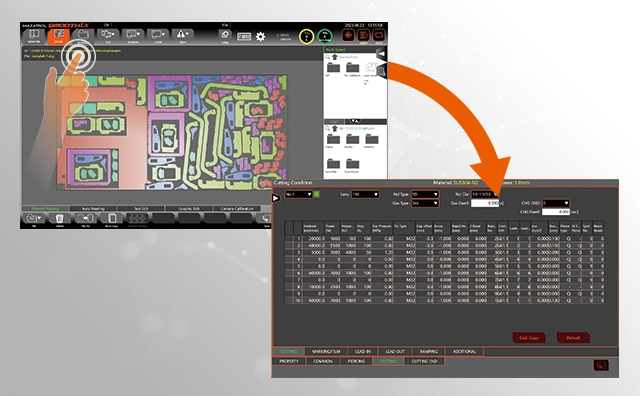

Operator can easily zoom in and out on the display screen with their fingertips. The wide screen also allows the operator to check nesting at a glance.

Flat design for easier operation

Apart from the emergency stop and rotary switch buttons, operational buttons feature a flat design. The use of pictograms makes operation more intuitive.

Dual Monitor

Operator can work while referring to the cutting area and manual.

* Dual Monitor is optionally available on OPTIPLEX NEO.

One-touch operation

All necessary information, such as the cutting condition database, can be called up with a single touch. It is now easier to operate.

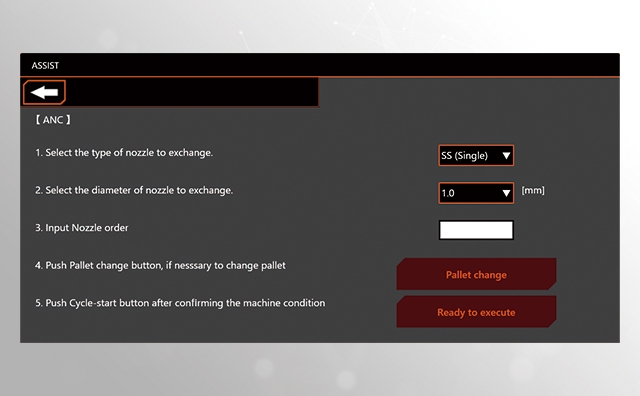

Assist functions

By simply entering the items suggested by assist functions, the operator can easily set up functions such as a nozzle centre check and automatic nozzle change.

Touch panel type CNC system for ease of operation

15” touch panel colour LCD screen as standard. The simple and easy-to-understand screen layout improves operability. Frequently used displays, such as the command screen, position screen, and programming screen can be easily moved. Optimal acceleration / deceleration control enables both stable high-speed and high-accuracy cutting and reduction of cutting time.

CNC control for 3D laser processing machines

New generation CNC system specialised for pipe processing

3D laser processing of pipes and structural materials can be easily achieved with high-accuracy. Through years of development, the system has incorporated accumulated expertise to greatly enhance operability and productivity.

- New graphical user interface specialised for tube processing ensures easier operation

- With the flow from preparation to processing displayed on one screen it is easy to operate

- Condition setting of scheduled operation can be changed and reprocessing can be done on the CNC system easily