| Spindle bore | Φ61 mm |

| Chuck size | 6″ |

| Max. machining diameter | Φ245 mm |

| Max. machining length | 605 mm |

CNC Turning Centres

QRX

- Upper and lower turrets enable significant reduction in cycle time

- Easy programming of balance cutting and simultaneous left and right machining with the conversational MAZATROL program

- A wide range of automation options to enhance productivity, including bar feeders, workpiece unloaders and automatic parts catcher

QRX-50MY SG (Tailstock spec.)

Simultaneous machining with upper and lower turrets enables efficient mass-production machining of shaft shapes.

QRX-50MSY SG (Second spindle spec.)

The 2 turret and 2 spindle machine construction allows simultaneous left and right hand machining, enabling efficient mass-production of bar shapes.

Bar work capacity

| Machine model | Main spindle | Second spindle |

|---|---|---|

| QRX-50MY SG | Φ52 mm | - |

| QRX-50MSY SG | Φ52 mm | Φ52 mm |

Space-saving design

Space-saving design that takes floor space into consideration; optimal placement including bar feeder achieves the smallest width in its class

Pursue even higher productivity through automation

A variety of automation equipment such as bar feeders, workpiece unloaders and a auto parts catcher are optionally available, enabling long-term automatic operation.

Bar feeder and workpiece unloader

(QRX-50MSY SG)

While the main spindle is processing, the finished product on the second spindle is removed from the machine, allowing for continuous automatic operation without impairing the machine’s cycle time. The specification of the work unloader can be chosen between a hand type and a bucket type.

Auto parts catcher

The bucket attached to the lower turret is used to transport the finished products from the first spindle and the second spindle (for MSY), as well as the bar remnants.

12 position drum turret (24 positions) as standard equipment

The turret is a drum turret with minimal interference and the BMT45 tool holder mounting system is used. The tool holder can be reversibly mounted at 180°.

CNC system MAZATROL SmoothG

Large touch screen for intuitive operation

Highly efficient machining with 2 turret dedicated display and support functions

The display is divided into two columns making it easier to confirm the operation of each turret. The EIA/ISO programming screen displays the waiting command positions side by side, enabling intuitive and easy programme editing.

Various programme check functions

Virtual Machining

Accurate simulation under the same operating environment as the machine enables us to check the machining shape and interference in advance. This enables highly productive operations from the first production piece.

Safety Shield

Even when axes are moved manually during setup work, the 3D model on the NC screen checks for interference and alerts the operator to prevent machine interference.

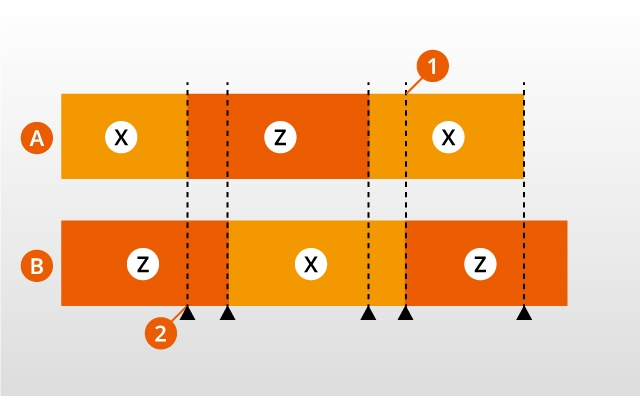

Inter-grid single block operation

When one turret completes a process, all turrets in operation stop simultaneously, even if the end of the block differs for each turret. This inter-grid single block operation ensures the synchronisation between turrets, preventing interference and increasing downtime caused by programme misalignment.

A: Turret A

B: Turret B

1: When turret B X-axis feed reaches ▲, turret A also stops.

2: When turret A X-axis feed reaches ▲, turret B also stops.

▲: Operation stop

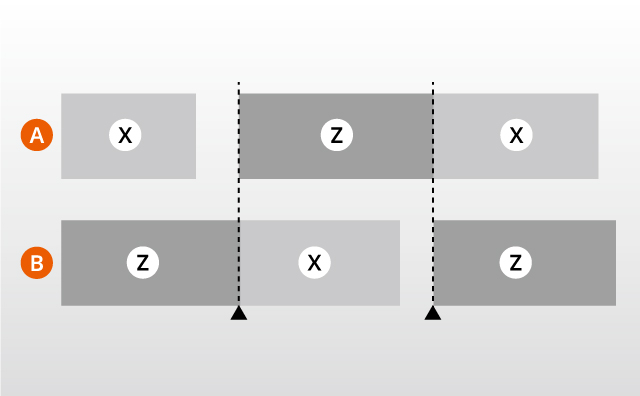

A: Turret A

B: Turret B

▲: Operation stop

Override synchronised operation

Override, which allows adjustment of programme processing time, is reflected not only in the operating time of the turrets but also in the standby time, thus enabling programme operation without disrupting synchronisation between turrets. This allows for high-accuracy interference checks.

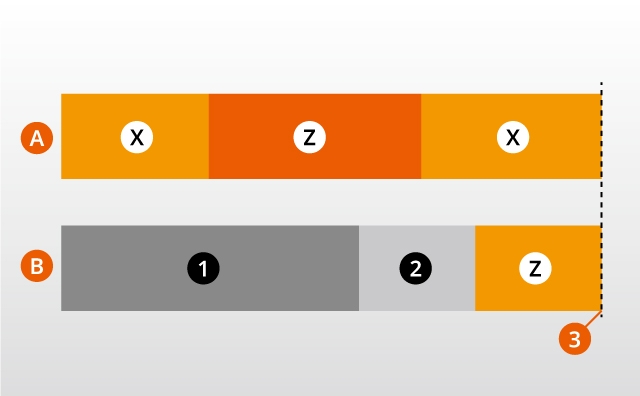

A: Turret A

B: Turret B

1: Dwell (standby time)

2: Supporting Functions

3: No programme misalignment

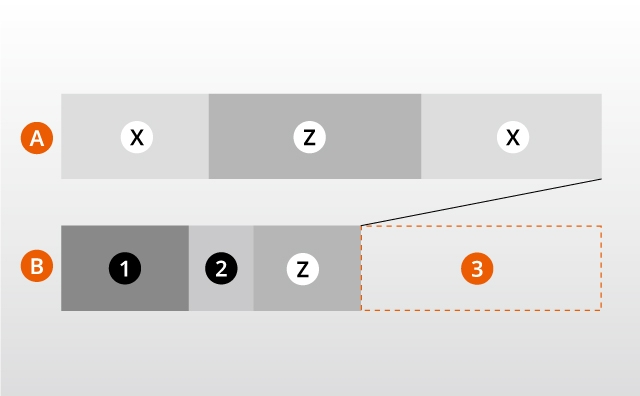

A: Turret A

B: Turret B

1: Dwell (standby time) No change in time

2: Supporting Functions

3: Program misalignment occurred

Manual pulse handle operation

The machining programme can be operated at any speed by turning the handwheel of the CNC system by hand. The approach position and points where interference is likely to occur can be carefully checked.

QRX-50MSY SG

QRX-50MY SG

| Spindle bore | Φ61 mm |

| Chuck size | 8″ |

| Max. machining diameter | Φ245 mm |

| Max. machining length | 552 mm |