| Max. worksheet width | 1525 mm |

| Max. worksheet length | 3050 mm |

| Laser power | 15.0 kW / 20.0 kW |

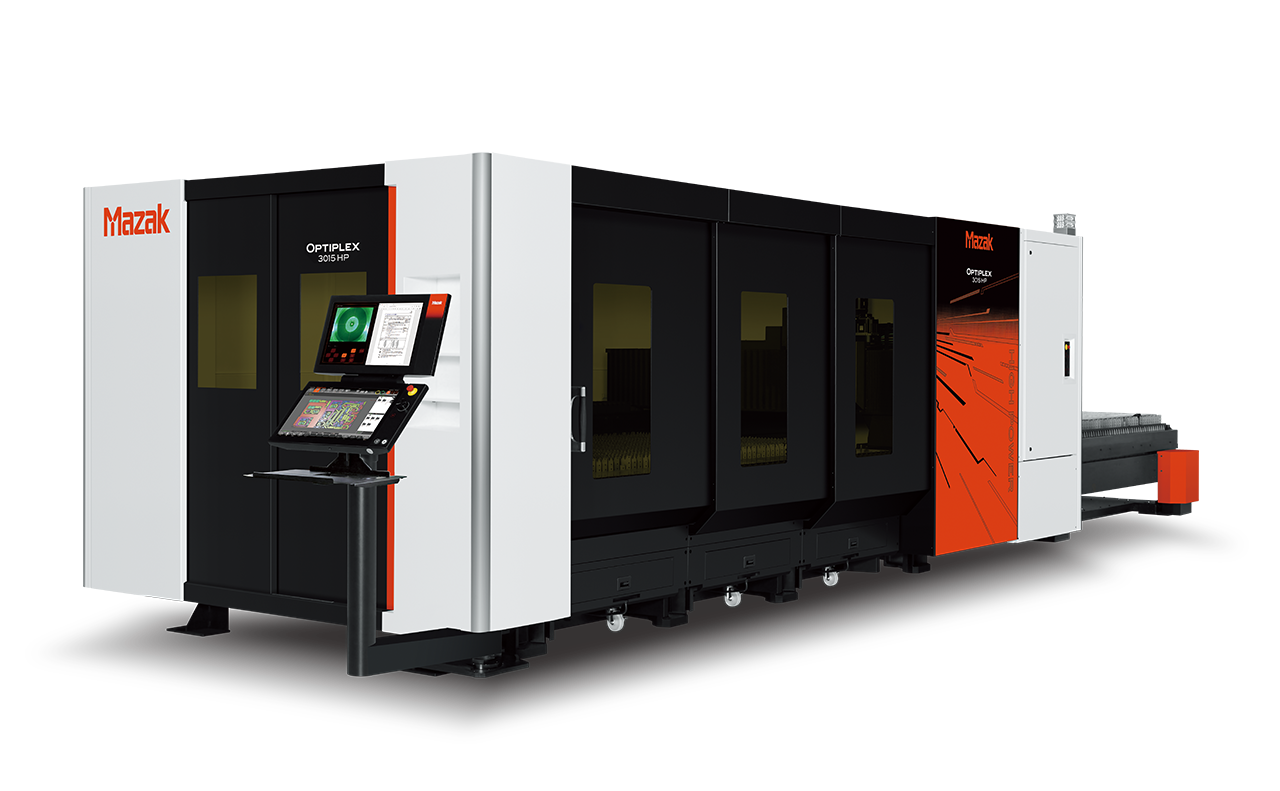

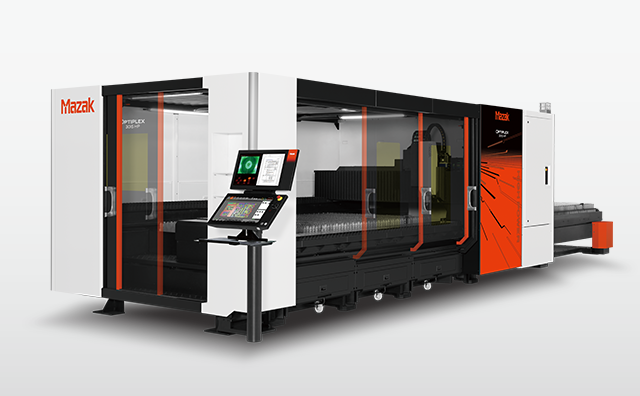

Laser Processing Machines

OPTIPLEX HP

- Equipped with Mazak SmoothCUT 15.0 kW and 20.0 kW laser oscillator

- Laser processing technology “GRAND CUT” enables stable continuous machining of thick materials

- Design focused on usability and ease of operation

- Equipped with proprietary resonator “Mazak SmoothCUT”

- Equipped with CNC system MAZATROL SmoothLx

Achieves high speed and high quality processing

Mazak SmoothCUT and GRAND CUT raise the temperature of the molten iron while cutting to improve quality of the cut surface. In addition, In 25 mm thick mild steel, perpendicularity has been improved by more than 80% compared to conventional machines. High-quality continuous machining of thick mild steel materials up to a thickness of 50 mm, can be performed stably, while minimizing the occurrence of processing defects.

A: Cut surface using a general oscillator

B: Cut surface of a material with thickness of 50.0 mm using GRAND CUT + Mazak SmoothCUT

Wide open doors for easy loading and unloading

Wide opening doors

Sliding doors are installed on the front and side face of the machine, minimizing the floor space required. The OPTIPLEX 3015 HP has a large opening space of 1200 mm at the front face and 3210 mm at the side face, while the OPTIPLEX 4220 HP has an opening space of 1190 mm at the front face and 3130 mm at the side face. It ensures easier loading and unloading.

Easy adjustment of nozzle center

Integrated Nozzle Camera

A camera is mounted next to the nozzle holder to check the center position of the nozzle. The nozzle center can be easily adjusted by turning the dial while viewing the operation screen.

Automatic detection of machining area for nesting

Camera Network Nesting (option)*

Camera inside the machine detects the remnant material and automatically identifies the cutting area for nesting.

- * MAZAK SMART SYSTEM is required for Camera Network Nesting.

Wide and flat screen for easier operation

CNC system MAZATROL SmoothLx

The 21.5- inch wide screen allows you to see all the nested materials at a glance. Apart from the Emergency Stop and Rotary Switch buttons, operational buttons feature a flat design. Pictograms make the operation more intuitive and user-friendly.

Large 21.5” LCD screen and touch panel

Operator can easily zoom in and out on the display screen with fingertips. The wide screen also allows the operator to check nesting at a glance.

Flat design for easier operation

Apart from the Emergency Stop and Rotary Switch buttons, operational buttons feature a flat design. The use of pictograms makes operation more intuitive.

Dual monitor

Operator can work while referring to the cutting area and manual.

One-touch operation

All necessary information, such as the cutting condition database, can be called up with a single touch. It is now easier to operate.

Assist functions

By simply entering the items suggested by assist functions, operator can easily set up functions such as nozzle center check and automatic nozzle changing.

Improved operability of CNC control

The rotating CNC control panel gives operators the option to work at the front or side of the machine. The screen also tilts, offering a comfortable operating position for all users.

Proprietary fiber laser oscillator achieves high quality and high productivity

Mazak SmoothCUT

- Mazak SmoothCUT achieves reliable beam quality across a wide range of materials and thicknesses, with optimized performance for thick plate cutting.

Cloud-based membership service to support customers

"Mazak iCONNECT TM " is a service that supports improvement of productivity by connecting "customers," "Mazak machines," and "Mazak support centers" with the latest technology. We provide a wide range of services and support, including processing assistance, operation monitoring, and maintenance support.

Our laser processing machines comes with a free use of our M2M service for 3 years.

The M2M service is a paid service that utilizes various information contained in machines by connecting them to the internet.

Some functions are available through the machine's CNC system.

Applicable Models | OPTIPLEX 3015 HP | STX-2412 | FG-400 NEO |

|---|

Example of M2M service

Remote diagnosis of machines

By connecting the Mazak support center with your machine and checking its condition, problems can be resolved as quickly as possible. We provide advice on machining programs and help with quick recovery from machine trouble, reducing machine downtime.

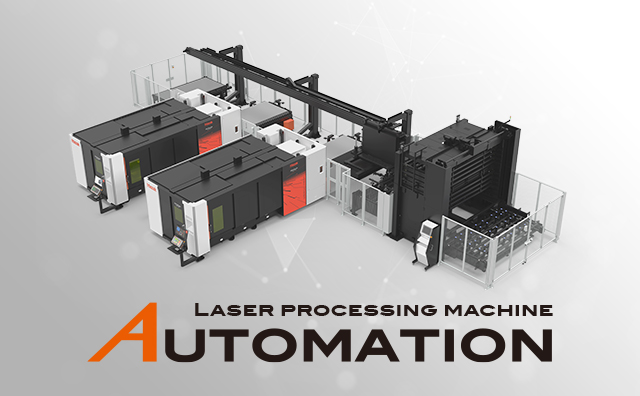

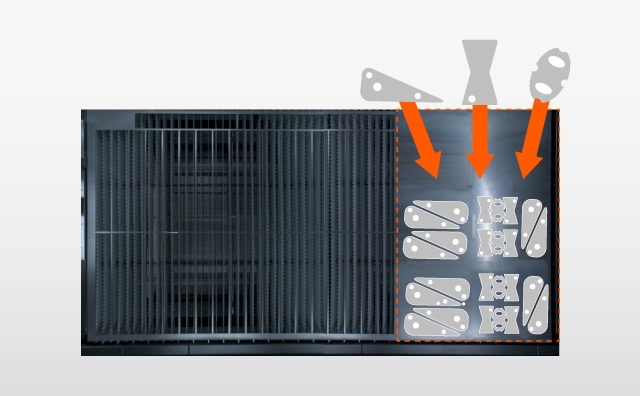

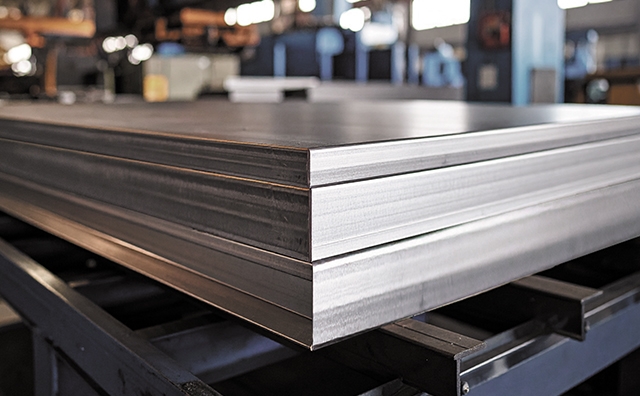

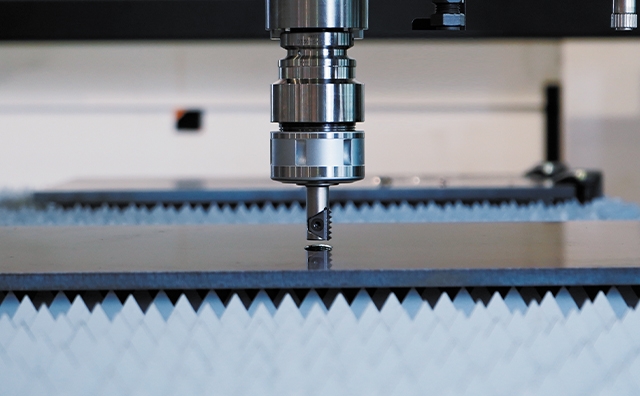

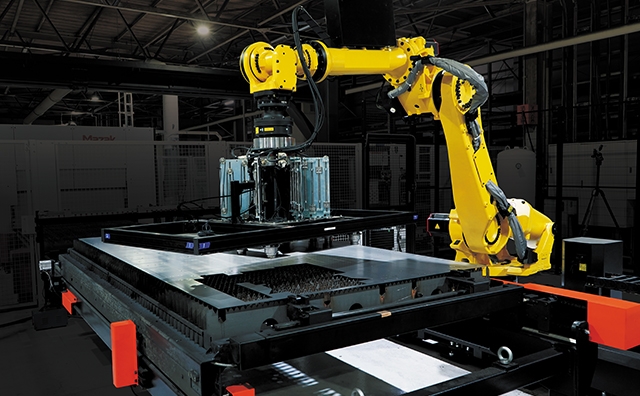

MAZAK LASER FA SYSTEM

From material supply to laser processing, tapping, and sorting, all of them can be completed automatically.

The flow of automation

- Image-1

- Image-2

- Image-3

- Image-4

Reference Video

OPTIPLEX 3015 HP

OPTIPLEX 4220 HP

| Max. worksheet width | 2050 mm |

| Max. worksheet length | 4120 mm |

| Laser power | 15.0 kW / 20.0 kW |