| Pallet size | □400 mm |

| Tool shank | BT40 |

| Max. spindle speed | 12000 min-1 (rpm) |

| Max. workpiece size | Φ630 mm × 900 mm |

Horizontal Machining Centers

HCN NEO

- A wide range of spindle variations that allow machining under optimal cutting condition

- Reduced non-operating time and improved productivity with NC rotary table (standard equipment)

- Long-term, high precision machining made possible by high rigidity structure and state-of-the-art compensation technology

- Wide variety of automation systems are available

- Improved environmental performance with energy-saving equipment

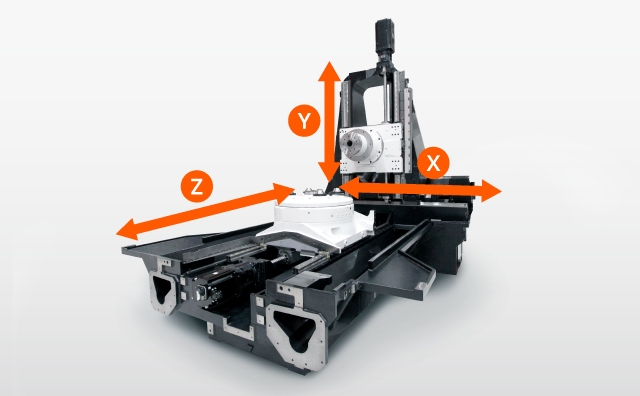

Largest X, Y, and Z-axis stroke and workpiece size in its class

HCN-4000 NEO

| Pallet Dimension | 400 mm × 400 mm |

| X-axis / Y-axis / Z-axis stroke | 560 mm / 640 mm / 640 mm |

HCN-5000 NEO

| Pallet Dimension | 500 mm × 500 mm |

| X-axis / Y-axis / Z-axis stroke | 730 mm / 730 mm / 800 mm |

HCN-6800 NEO

| Pallet Dimension | 630 mm × 630 mm |

| X-axis / Y-axis / Z-axis stroke | 1050 mm / 900 mm / 980 mm |

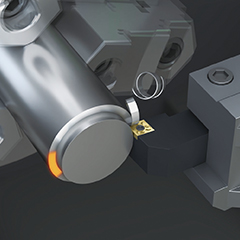

Spindle specifications to meet a wide variety of machining requirements

The high-rigidity spindle can perform heavy-duty machining of challenging materials and steel, and high-speed machining of non-ferrous materials such as aluminum.

High-speed and high-torque options are available.

HCN-4000 NEO / HCN-5000 NEO Tool shank: BT40

Standard specification: 12000 min-1

Spindle output

18.5 kW (25 HP) [40% ED]

15 kW (20 HP) [Cont. rating]

Max. torque: 81.9 N・m [40% ED]

High torque specification 15000 min-1 (Option)

Spindle output

46 kW (62 HP) [40% ED]

37 kW (50 HP) [Cont. rating]

Max. torque: 200 Nm [40% ED]

High speed 18000 min-1 (Option)

Spindle output

35 kW (47 HP) [40% ED]

26 kW (35 HP) [Cont. rating]

Max. torque: 84 Nm [40% ED]

High speed, high output 20000 min-1 (Option)

Spindle output

42 kW (56 HP) [40% ED]

26 kW (35 HP) [Cont. rating]

Max. torque: 161 Nm [40% ED]

Ultra-high speed 25000 min-1 (Option)

Spindle output

23 kW (31 HP)[40% ED]

15 kW (20 HP) [Cont. rating]

Max. torque: 22 Nm [40% ED]

HCN-6800 NEO Tool shank: BT50

Standard 10000 min-1

Spindle output

AC 45 kW (60 HP) [40% ED]

AC 37 kW (50 HP) [Cont. rating]

Spindle torque: 350 N・m (35.68 kgf・m) [40% ED]

High torque 8000 min-1 (Option)

Spindle output

AC 55 kW (73 HP) [25% ED]

AC 45 kW (60 HP) [Cont. rating]

Max. torque: 1413 N・m (144 kgf・m) [10% ED]

High speed 16000 min-1 (Option)

Spindle output

AC 37 kW (50 HP) [40% ED]

AC 30 kW (40 HP) [Cont. rating]

Spindle torque: 221 N・m (22.53 kgf・m) [40% ED]

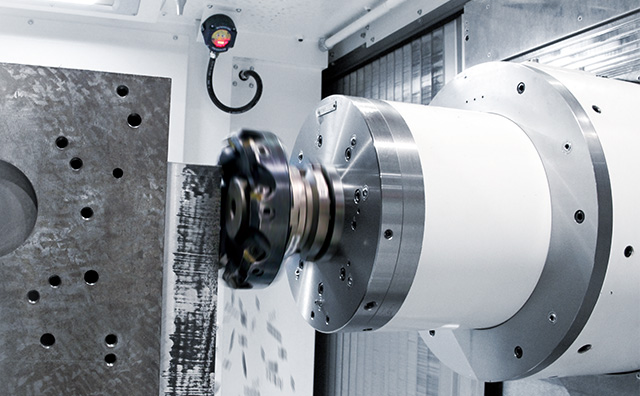

High-rigidity machine construction for stable machining performance

High-rigidity bed

The high-rigidity X-, Z-axis roller guide ensures stability during X- and Z-axis travel.

X-axis slanted design

The mounting surfaces of the X-axis linear guide rails are at different heights to ensure high rigidity and lower total weight. High-speed, high-precision positioning is achieved by driving close to the center of gravity.

Linear roller guides utilized on all axes

The HCN series uses linear roller guides on the X-, Y- and Z-axis for high accuracy and heavy-duty machining.

Rapid traverse rate, maximum feedrate 60 m/min (X, Y, Z axis)

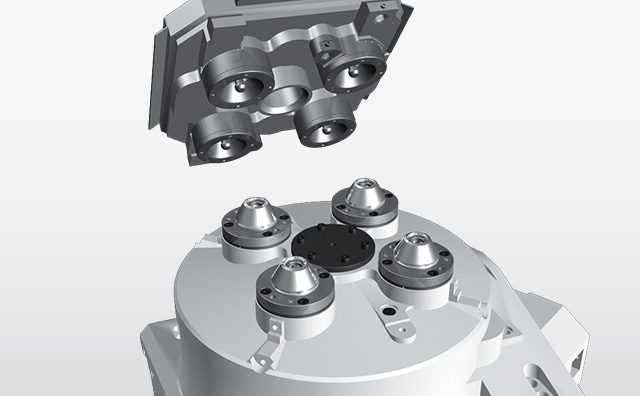

Cone coupling

The pallet and table are clamped by cone couplings to ensure high rigidity and high repeatable positioning accuracy when changing pallets.

Automated system best suited for multi-product processing

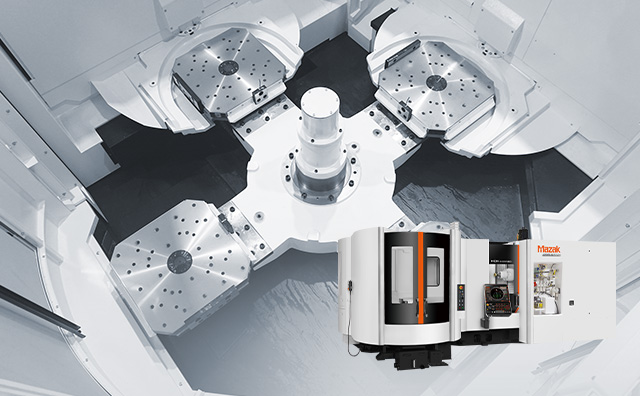

PALLETECH SYSTEM (Option)

The modular design of the PALLETECH conveniently allows more machines and increased pallet storage capacity to be added to the system after the initial installation in response to changing production requirements. The pallet stocker is available with one, two and three levels for large pallet storage capacity with small floor space requirements.

| Minimum | Maximum | ||

|---|---|---|---|

| Machine(s) | 1 | 15 | |

| Number of pallets | 1 level | 6 | 240 |

| 2 levels | 12 | 240 | |

| 3 levels | 18 | 240 | |

| Loading station(s) | 1 | 8 | |

| Loading robot | 1 | 1 | |

Software for automatic operation and management of PALLETECH

PMC NEO

- Simulations based on actual machine data allow for quick and easy optimization of system operation plans.

- It assists with the setup of tools and materials required for system operation.

- Remote operation monitoring is available from an office PC, tablet, or smartphone.

Pallet Changer

For higher productivity, set up the next workpiece during machining of the current workpiece.

6-pallet changer (Option)

Set up multiple workpieces for automatic operation over extended periods of time.

MPP (MULTI PALLET POOL) (Option)

- * |Compatible with HCN-4000 NEO and HCN-5000 NEO

Maximum of 16 pallets can be stored in the pallet stocker. It will help automating the process with minimal space.

Hydraulic fixtures for higher productivity

Hydraulic power supply A (supply from machine top) (Option)

Hydraulic hoses supply hydraulic power from the top part of the pallet changer to fixtures mounted on each pallet.

Maximum of 12 ports can be arranged. High-power hydraulic supply with 21 MPa is available.

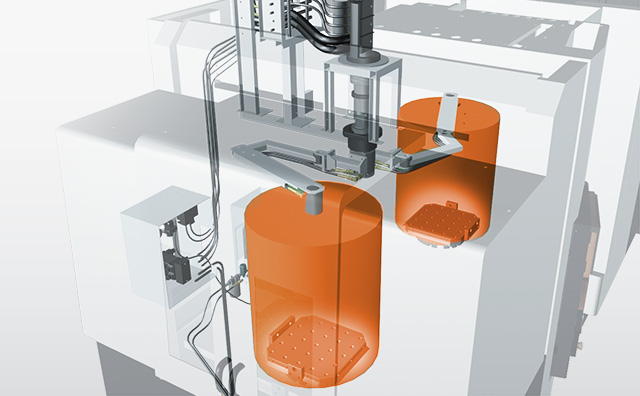

Hydraulic power supply B (supply through pallet) (Option)

A leak-free coupling system supplies hydraulic power to the supply port on the bottom of the pallet. Unlike hydraulic power supply from machine top, this system requires no hydraulic hose or hydraulic rotary coupling. This minimizes interference for easy fixture design and workpiece machining. High-power hydraulic supply with 21 MPa is available.

Loading station: Maximum of 8 ports

Inside machine: Maximum of 4 ports

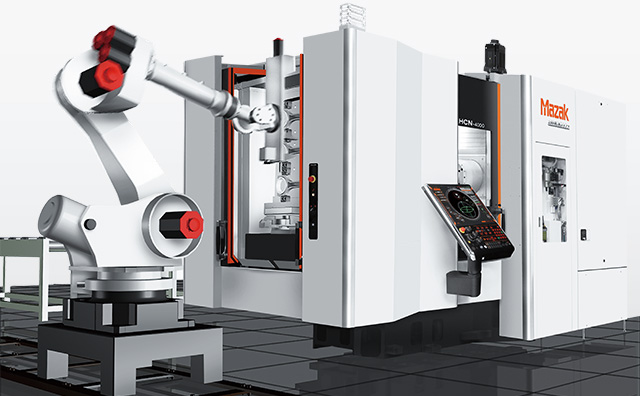

Robot System (Option)

Interface for connecting an external robot for workpiece loading / unloading to / from automatic hydraulic fixtures is optionally available.

◎ Field network available

Improved environmental performance with energy-saving equipment

Energy Saver

Energy consumption and the regenerative power produced through the energy saving equipment can be viewed visually on the CNC system to stimulate awareness of energy conservation. In addition, the system can control coolant and other equipment based on the cutting amount to reduce power consumption.

* An optional Smooth coolant system is required for the control of coolant and other equipment.

Environmentally friendly Smooth coolant system*

Optimal control of coolant discharge amount

Energy saver automatically determines the optimal coolant discharge for energy-saving machining. Processing with reduced power consumption is possible at all times.

* Option

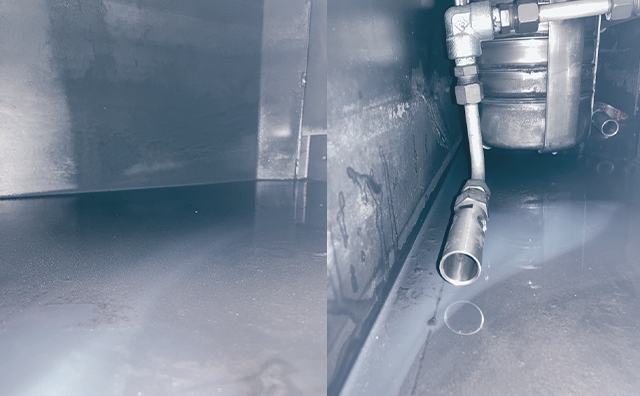

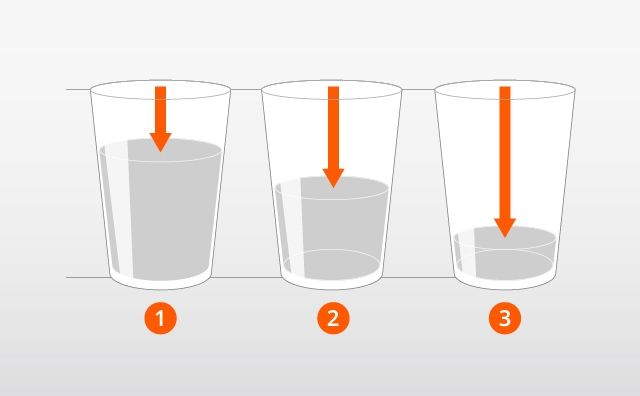

Energy-saving coolant system with sludge removal performance

No need to frequently clean the tank

The coolant tank has a coolant jet that makes a vortex in the center so that small machined chips will not settle in the tank. This feature makes it possible to keep the coolant tank clean and extend the service life of the coolant. Ease of maintenance is also ensured. The frequency of coolant changes is reduced as well as CO₂ emissions at coolant disposal.

Smooth Coolant System installation results

- The conventional coolant tank

- Smooth Coolant System

Reference Video

HCN-4000 NEO

HCN-5000 NEO

| Pallet size | □500 mm |

| Tool shank | BT40 |

| Max. spindle speed | 12000 min-1 (rpm) |

| Max. workpiece size | Φ800 mm × 1000 mm |

HCN-6800 NEO

| Pallet size | □630 mm |

| Tool shank | BT50 |

| Max. spindle speed | 10000 min-1 (rpm) |

| Max. workpiece size | Φ1050 mm × 1300 mm |